Input/Output¶

Status¶

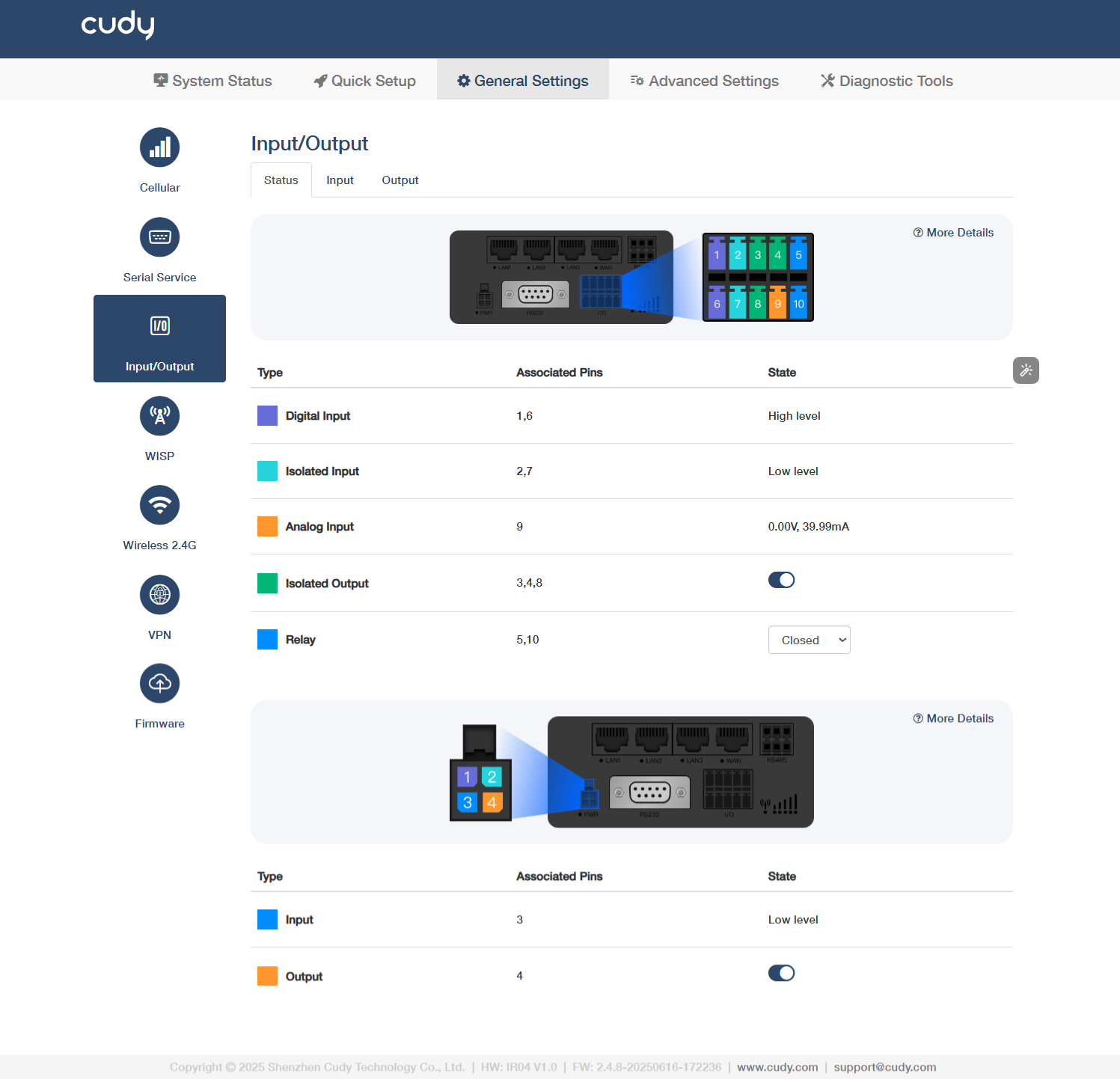

I/O¶

-

Digital Input (Associated Pin 1/6): Detects high-level signals (e.g., 24V) for equipment status monitoring (limit switches/sensors).

-

Isolated Input (Associated Pin 2/7): Reads low-level signals (0V) with galvanic isolation (≥1500V) for safety interlock/emergency stops.

-

Analog Input (Associated Pin 9): Supports 0-10V/4-20mA signals for precision measurement (temperature/pressure transmitters).

-

Isolated Output (Associated Pin 3/4/8): Transistor outputs (On=0V, Off=high-Z) for driving relays/solenoids (≤0.5A load).

-

Relay (Associated Pin 5/10): Electrically isolates control circuits from power circuits (e.g., 5V PLC → 240V motor). Select Closed (NO) when energized (current flows to load) or Open (NC) when de-energized (failsafe/default state).

![]() Use ferrite beads on analog wires to suppress EMI in noisy environments.

Use ferrite beads on analog wires to suppress EMI in noisy environments.

PWR¶

-

Input (Associated Pin 3): Receives external power to activate the device.

◦ High Level (Typ. 24V±10%): Normal power reception, device operational

◦ Low Level (<1V): Power loss/undervoltage (check wiring/supply voltage)

◦ Floating: Open circuit (verify terminal connection integrity)

-

Output (Associated Pin 4): Supplies regulated power to connected peripherals.

◦ On: Actively supplying power to peripherals (e.g., 24V/5V output enabled)

◦ Off: Output disabled (manual shutdown or protection triggered)

Input¶

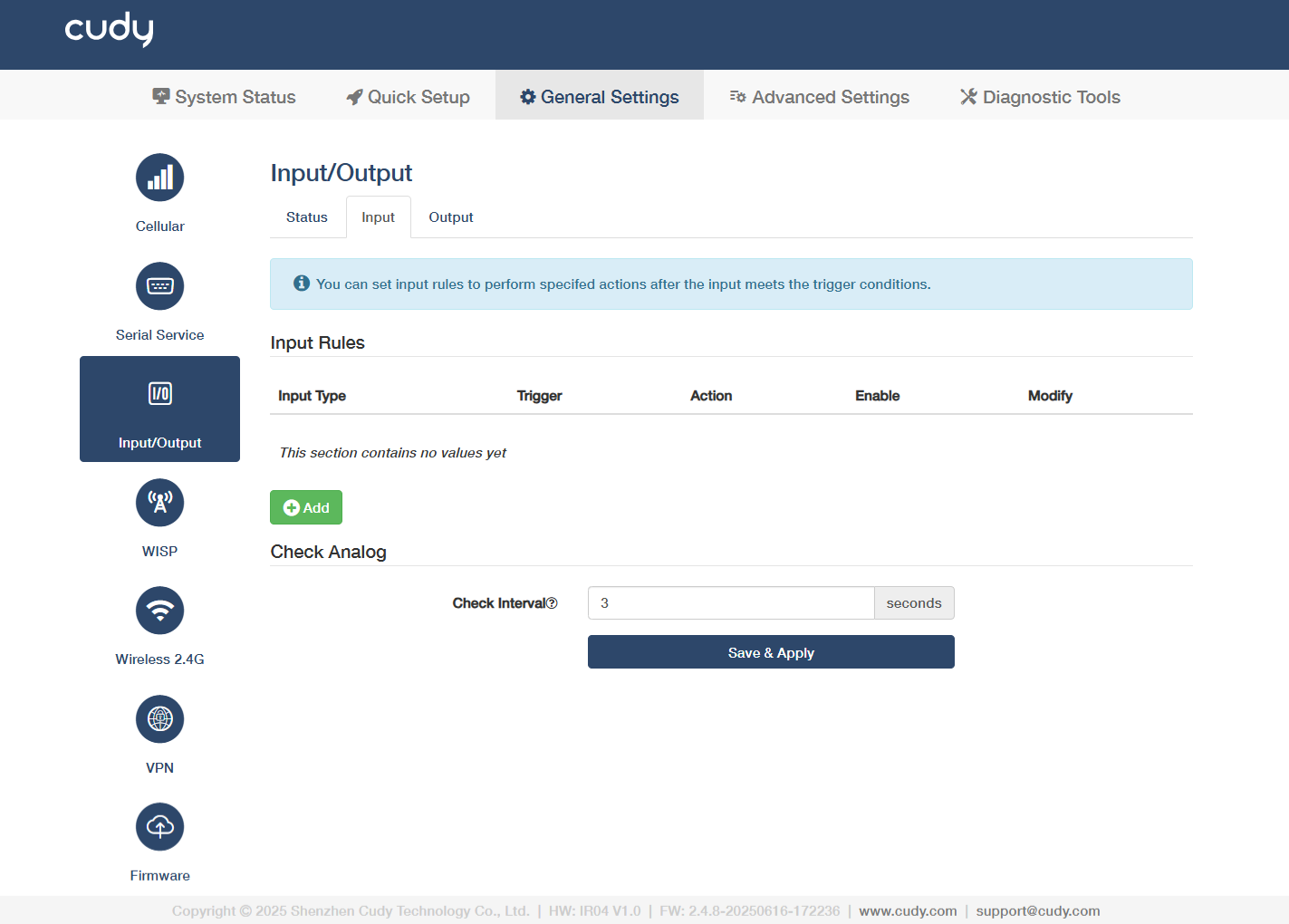

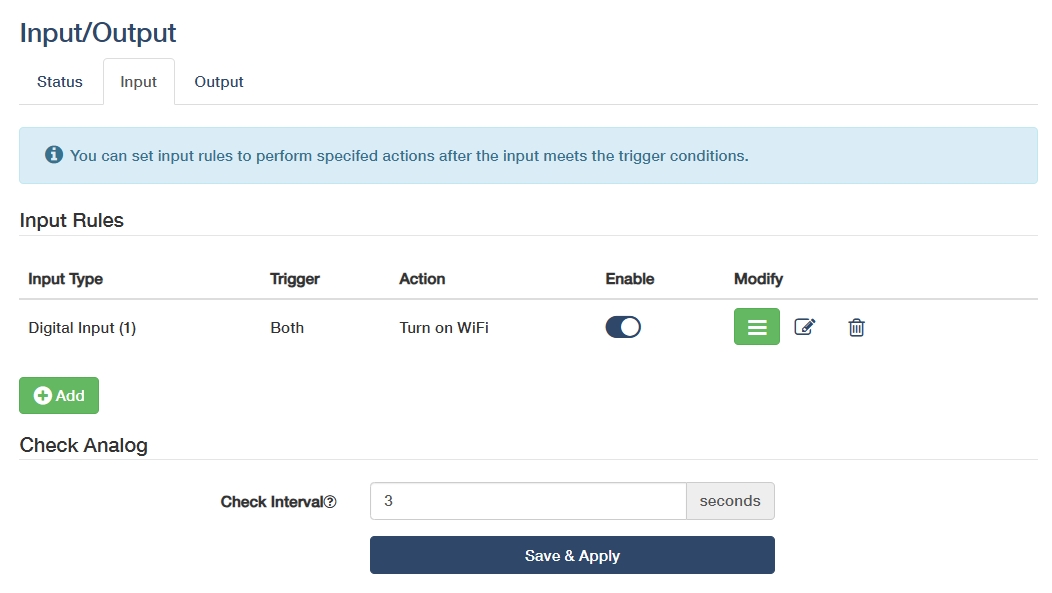

- Add: Click to configure input rules to perform specified actions after the input meets the trigger conditions.

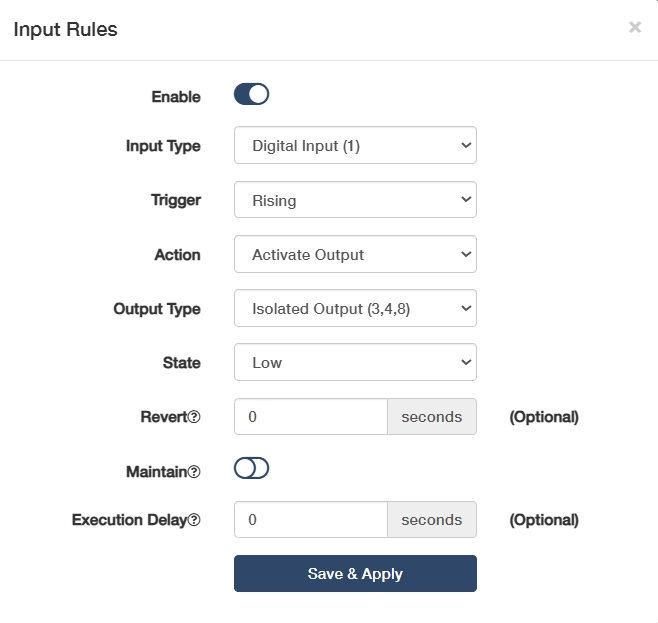

- Enable: Enable this entry of input rule.

-

Input Type: Select to define the signal category (e.g., digital/analog/pulse).

◦ Digital Input(1): Standard binary input for detecting 24V signals.

◦ Isolated Input(2,7): Galvanically separated input for safety-critical signal.

◦ Digital Input(Power Socket 3): Power-monitoring input, detecting mains voltage presence via socket status.

◦ Analog Input(6,9): Reads 0-10V/4-20mA signals for precision measurement.

-

Trigger: Select a condition to activate the rule.

◦ For Digital/Isolated Input: Rising triggers when signal transitions from low to high, ideal for power-on events; Falling triggers when signal transitions from high to low, used for emergency stop detection; Both responds to any voltage change, perfect for pulse counting or state monitoring.

◦ For Analog Input: Inside Range triggers when the signal stays between Min/Max values; Outside Range triggers when the signal exceeds Min/Max thresholds.

-

Analog Type (for Analog Input): Select to match your sensor's output signal type. Current (mA) is used for 4-20mA/0-20mA industrial sensors (like pressure transmitters) as it’s resistant to signal degradation over long distances; Voltage (V) is used for 0-10V/±10V signals (like position sensors) with simpler wiring but shorter effective range due to voltage drop.

- Minimum (V) / Maximum (V) (for Analog Input): Set voltage thresholds to define the valid range for voltage-based triggers.

-

Minimum (mA) / Maximum (mA) (for Analog Input): Configure current limits for current-loop device monitoring.

-

Action: Operation to execute when the rule is triggered.

◦ Activate Output: Triggers a designated output port. Then select a target Output Type and current input State, enter a Revert interval to determine auto-reset after trigger ends; enable or disable Maintain to decide lock state until manual reset.

◦ Send SMS: Send alert messages via cellular module, which requires configured GSM/GPRS parameters. Edit the SMS Text as needed, add the Phone number to send your SMS.

◦ SIM Switch: Automatically fails over to the selected backup SIM card when primary cellular signal is lost. Recommended to keep it Auto.

◦ Turn on WiFi: Enables the router's WiFi for wireless client connections.

◦ Turn off WiFi: Disables WiFi to conserve power or enhance security.

◦ Reboot: Restart the system to apply configurations or recover from faults.

-

Execution Delay:(Optional) Enter the time when will the action be executed after the rule being triggered.

-

Check Interval: Enter an interval in seconds to check analog input value.

-

Save & Apply: Click to save and activate the new settings or changes.

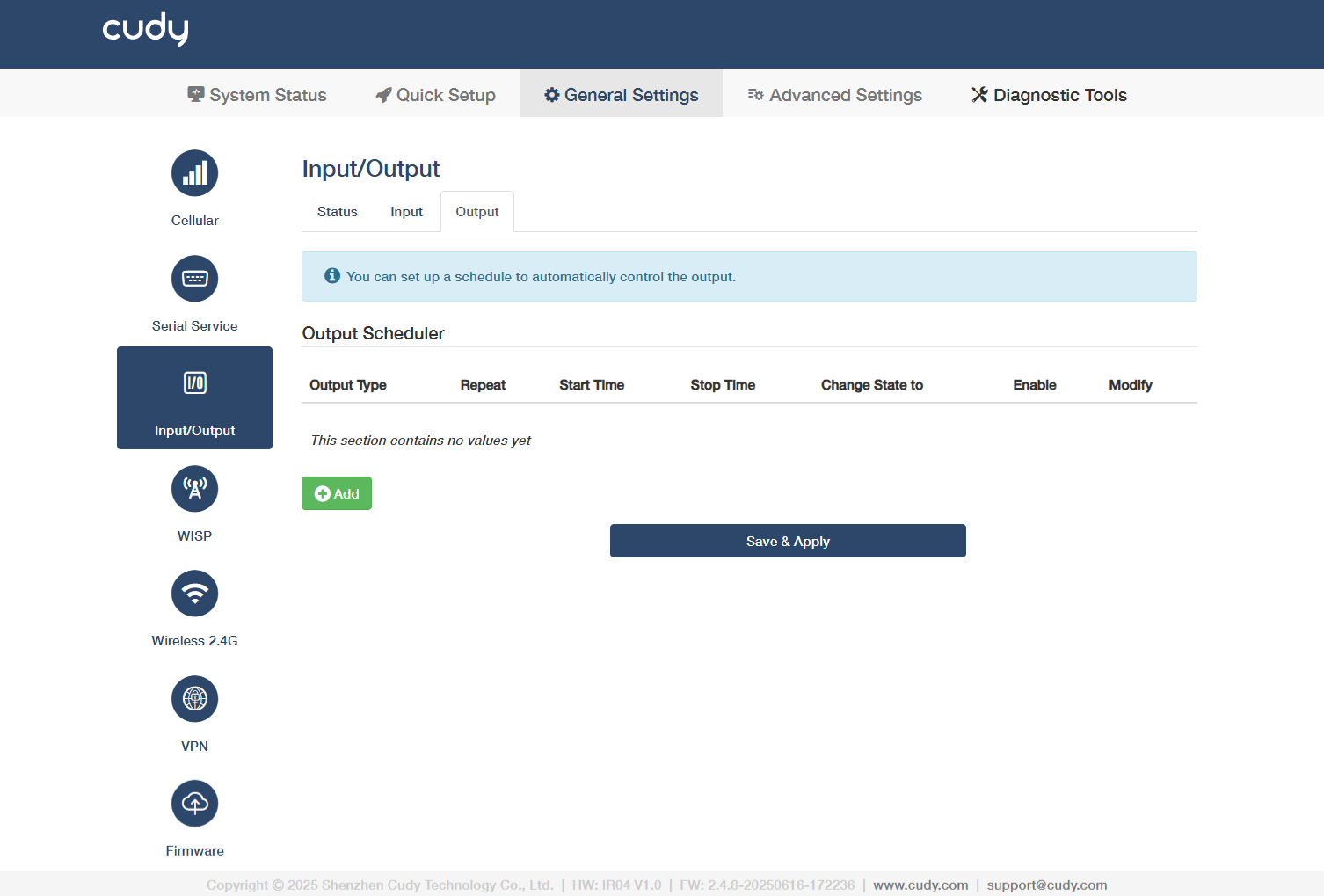

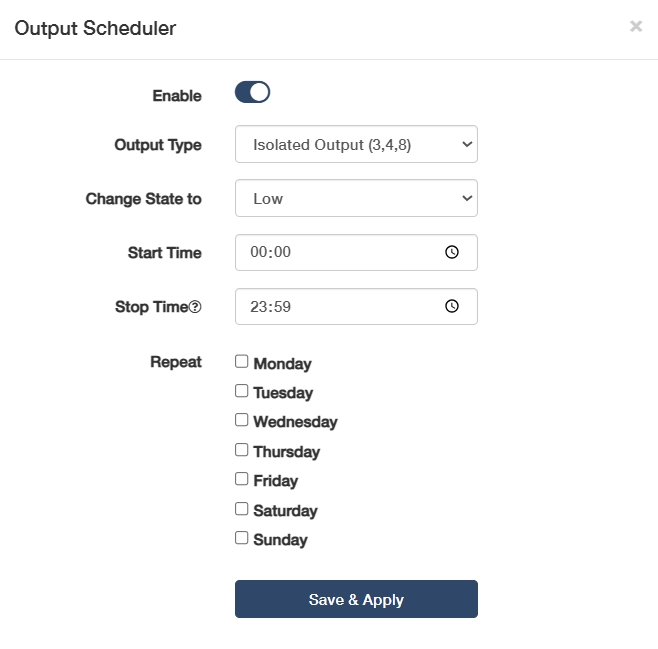

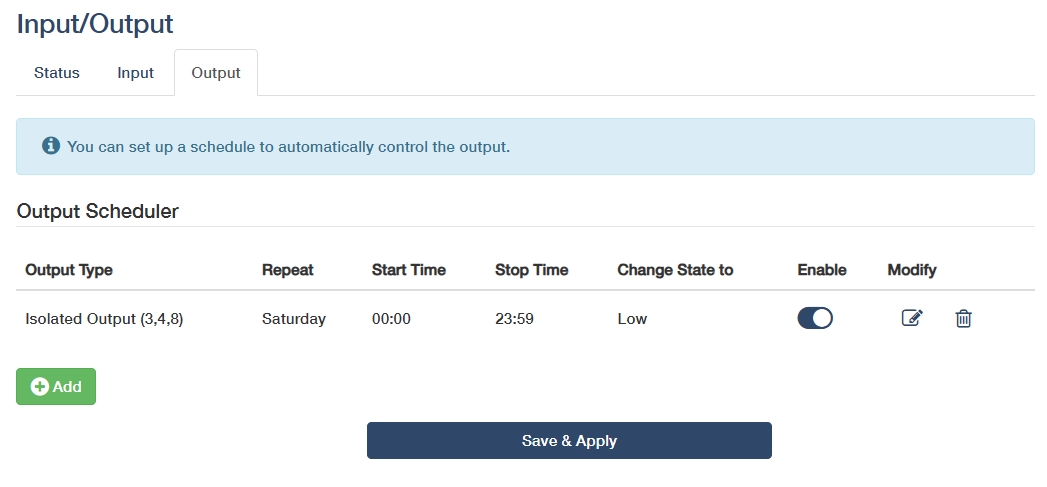

Output¶

- Add: Click to configure output scheduler to perform specified actions after the input meets the trigger conditions.

- Enable: Enable this entry of output scheduler.

-

Output Type & Change State to: Select to define the target output and state.

◦ Isolated Output (3,4,8): Galvanically separated outputs for sensitive equipment, preventing ground loops in PLC/SCADA systems. Then select Change State to High for activating the optocoupler/solid-state relay to send the preset voltage to the connected device, or Low for cutting off output voltage to create an open circuit.

◦ Relay (5,10): Electromechanical contacts for switching high-power loads. Then select Change State to Closed for physically connecting the relay’s internal contacts to allow current flow, or Open for breaking the contact to stop current flow.

◦ Output (Power Socket 4): Direct mains power control for appliances, with built-in overload protection. Then select Change State to High for enabling mains power output, or Low for disconnecting mains power (safety cutoff).

-

Start Time: Set an exact activation time for a-new-day shift start.

- Stop Time: Set a deactivation time for end-of-day shutdown.

-

Repeat: Select specific weekdays for cyclical automation of the output schedule.

◦ Weekdays (Mon-Fri): Ideal for factory equipment schedules (e.g., conveyor activation at 08:00-17:00).

◦ Weekends (Sat-Sun): Used for non-routine operations (e.g., backup system tests).

◦ 7-Day Cycle: For 24/7 critical systems (e.g., server room cooling).